Eugen Barilyuk

Published: 28 November 2024

←🏠 Back to eb43.github.io main page

News feeds almost daily publish about the latest breakthrough in batteries, and amid this flow of achievements that rarely go beyond the lab, you may have missed a real revolution. These are lithium-ion silicon-carbon (LSC) batteries, already being used in mass electronics that you can buy in stores. One of the first devices to adopt the new LSC battery technology are smartphones, and models with incredibly high capacity in the same thin casing are already being released.

There are several types of lithium-ion battery chemistries. Among the commercially widespread ones, you can mention lithium iron phosphate (LiFePo4), which are installed in charging stations and electric vehicles. Lithium titanate (LTO) batteries have very low capacity but charge instantly, are not afraid of the cold, and are used in stationary battery systems and electric transport.

Other common chemistries include lithium nickel cobalt aluminum (NCA), lithium manganese oxide (LMO), and lithium cobalt oxide (LCO).

Consumer electronics such as smartphones, laptops, headphones, tablets, and portable power banks use lithium nickel manganese cobalt (NMC) batteries. Until recently, NMC batteries had the highest capacity and the most affordable price, which is why they are used in mass compact technology.

In fact, each major family of lithium-ion batteries has many variations of its composition. For example, lithium-ion batteries with NMC chemistry can be:

But that's a topic for another article.

What's important to know is that almost half a decade ago, the lithium-ion NMC battery technology reached its limits. For example, smartphones plateaued at the 5000 mAh mark, and an additional 200-300 mAh were advertised as an incredible achievement. Of course, there were phones with 10 000 mAh and even 20 000 mAh batteries, but the increase in capacity was achieved solely by increasing the size and weight of the battery.

However, last year, smartphones appeared that, while maintaining the same size as a classic smartphone (7-9 mm thick with standard height and width), had significantly larger capacity. This became possible due to the use of lithium-ion silicon-carbon (LSC) batteries.

For example, the Chinese brand Realme recently released the GT 7 Pro smartphone with a 6500 mAh battery, and now it is preparing the GT 8 Pro model with a battery up to 8000 mAh. The exact specifications are still unknown – the company is exploring options with 7000, 7500, and 8000 mAh batteries.

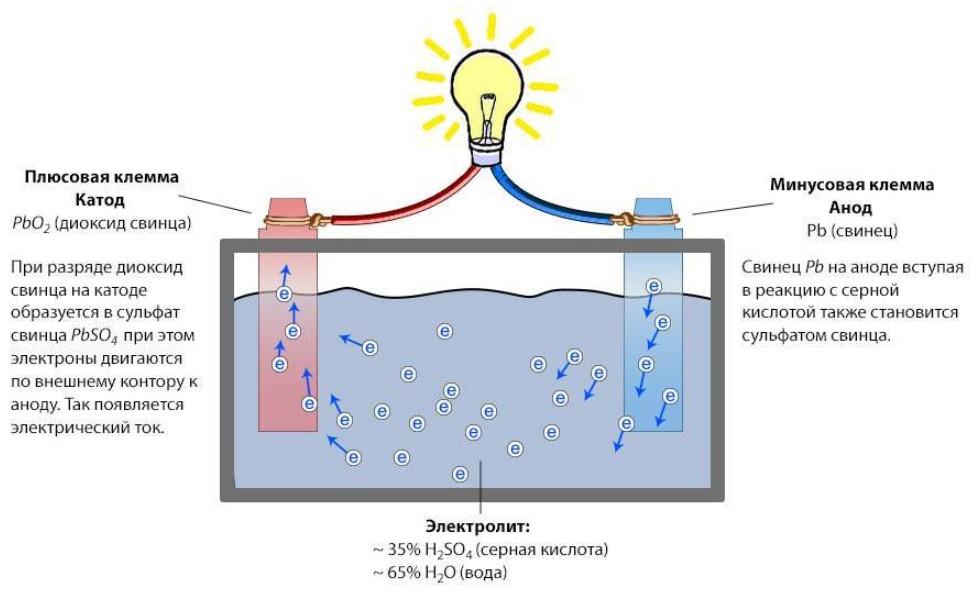

Any battery conceptually has a very simple structure. It is a sandwich made of three sheets of different materials soaked in electrolyte. The first and third sheets are charge carriers - the positive and negative sides of the battery. The second sheet is placed between them to prevent the first and second sheets from touching each other. The electrolyte is a liquid that helps charges move between the first and second sheets with minimal losses.

The difficulties in developing a battery arise when there is a need to achieve high capacity, high charge-discharge cycle count, the ability to deliver high current, and so on.

Scientists and engineers are constantly searching for materials for all three sheets and the electrolyte to create a battery from these materials that meets the desired parameters.

In Li-ion NMC batteries, which are installed in your current smartphone or laptop, one of the sheets (called the anode) consists of powdered charcoal (also known as carbon or graphite). However, the theoretical capacity of a lithium-ion battery with such an anode does not exceed 372 mAh/gram.

In LSC batteries, the anode contains both carbon and silicon. Adding silicon allows for a theoretical capacity of 3600 mAh (source: pv-magazine.com).

| Parameter | LiFePO4 | NMC | LSC |

|---|---|---|---|

| Energy Density | Lower (~90-150 Wh/kg) | Higher (~150-220 Wh/kg) | Very High (potential >300 Wh/kg) |

| Cycle Life | Very High (~2000-5000 cycles) | Moderate (~1000-2000 cycles) | Promising, still being tested |

| Safety | Excellent (stable chemistry) | Moderate (fire risk) | Under study |

| Cost | Higher initial cost, economically effective in the long term | Affordable | Likely high |

| Charge/Discharge Speed | From medium to high | High | Potentially very high |

| Operating Temperature | Wide range (-20°C to 60°C) | Moderate (-10°C to 50°C) | Under study |

| Applications | Energy storage, electric vehicles, solar batteries | Electric vehicles, portable electronics, tools | Advanced electric vehicles, energy-intensive needs |

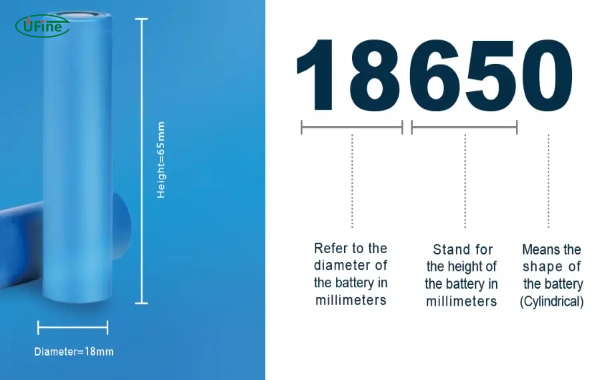

Tests show that after 100 charge-discharge cycles, the latest generation of LSC technology in 18650-format batteries (a popular format in flashlights, scooters, power banks, charging stations, and power tools) shows a 40% better result than lithium-ion batteries with graphite (source: hpqsilicon.com).

Thanks to LSC, soon we may see 18650-format batteries with 4000 mAh capacity on sale. Currently, 18650 batteries have a maximum capacity of 2700 mAh.

By the way, some 18650-format batteries are sold with labels claiming a capacity of 5000, 8000, 9000 mAh, etc. This is not true, and the batteries do not have the claimed capacity. There is currently no technology that allows packing such a capacity into a 18650 format.After 100 discharge cycles, the latest generation LSC battery with an initial capacity of 3883 mAh retained 3838 mAh (98.8%). In the chart below, its degradation is shown by the yellow line.

The common lithium-ion battery with a graphite anode deteriorated more, leaving only 2758 mAh from its initial capacity of 2780 mAh. This represents a capacity drop to 99.2%. Its degradation is shown by the blue line.

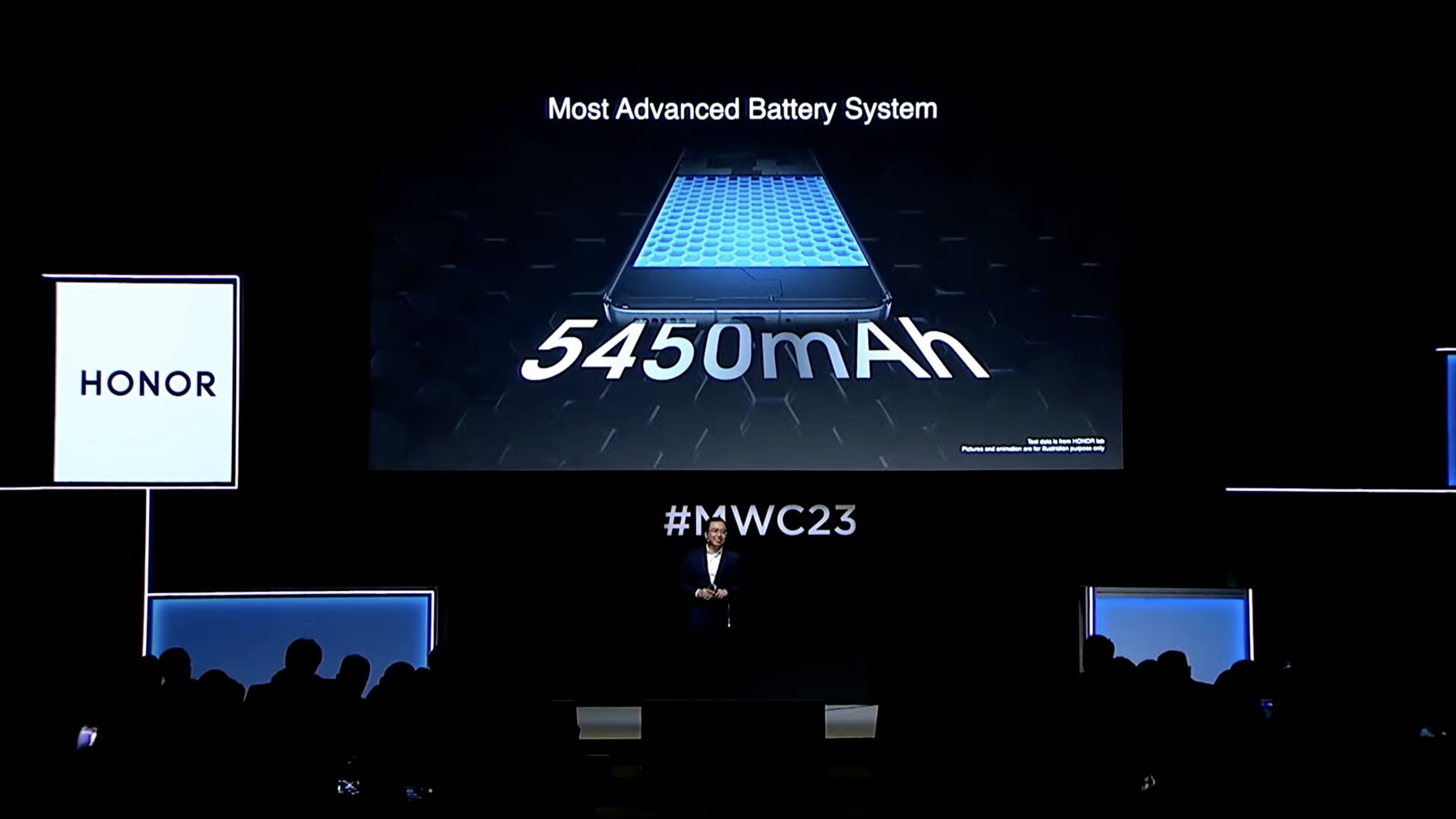

The first commercial smartphone with a lithium-ion silicon-graphite battery was introduced by Honor (a subsidiary of Huawei) at MWC 2023. It was the Honor Magic5 Pro, which featured a 5450 mAh battery. At the time, the standard battery capacity was considered to be 5100 mAh.

A representative from Honor emphasized that the silicon-graphite battery performs particularly well when the smartphone shows 1% charge (in fact, the battery still has 30% capacity at this point but is unable to use it).

A regular lithium-ion battery based on a graphite anode quickly loses capacity at a voltage of 3.6 volts (at which your phone shows 1% charge) if it is loaded (for example, by launching a game). The LSC battery holds the voltage 240% better in such moments.

In other words, a phone with a lithium-ion battery based on a graphite anode will suddenly turn off if you launch a game with only 1% charge left, while a phone with a lithium-ion silicon-graphite battery will last and not turn off.

After the Honor Magic5 Pro, flexible phones such as the Honor Magic V2 (5000 mAh) and Honor Magic 6 Pro (5650 mAh) quickly appeared. Flexible smartphones tend to have smaller capacities than standard “brick” smartphones, so this capacity is quite large for such devices.

The BBK Group quickly adopted silicon-graphite battery technology across almost all its subsidiaries. It released the Vivo X100 Ultra (5500 mAh), the flexible Vivo X Fold 3 Pro (5700 mAh). It also introduced the Oppo Find X8 with a 6000 mAh battery. Additionally, OnePlus 13 was released with a 6000 mAh battery. Don’t forget the models from Realme mentioned at the start of the article.

Xiaomi is also not falling behind, having introduced, for example, the Xiaomi 15 Pro with a 6100 mAh battery — 1220 mAh more than the previous model. The standard version of Xiaomi 15 also received a larger capacity battery compared to its predecessor thanks to the silicon-graphite lithium-ion battery.